Spring repairs for DIY enthusiasts

Spring maintenance of your tennis courts isn't rocket science; with the right tools and a few motivated volunteers, any club can manage it. Investing in good equipment once quickly pays for itself and offers several advantages.

- They save money every year

- You have control over the timing of the execution yourself.

- You can better take into account the specific characteristics of your tennis courts.

- They have funds available for other needed investments in the tennis club.

Turbo broom WR 870 Special

2.099,00 €

Tennis court milling machine SF 10

4.935,25 €

Aluminum hinges

86,00 €

Räumfix

1.150,00 €

Aluminum roughening rail

77,70 €

Special hinges

113,00 €

An important decision in the preparation is to what extent motor assistance is desired when scraping the tennis court surface.

While you can certainly scrape much more carefully and gently by hand, the ease of work provided by a motorized broom is immense.

They require significantly fewer helpers; even one man alone can scrape a tennis court with a turbo broom without too much effort.

The investment is of course significantly larger, however, with careful handling such a machine should be available for considerably longer than 10 years, which then puts the costs into perspective.

Shutter wood with saw blade

31,00 €

Ceiling profile sheet 150 cm

149,00 €

Basics of spring maintenance

During the winter, the tennis court loses its binding effect on the clay surface due to frost. This softens and must be treated in the spring to make the tennis court playable again.

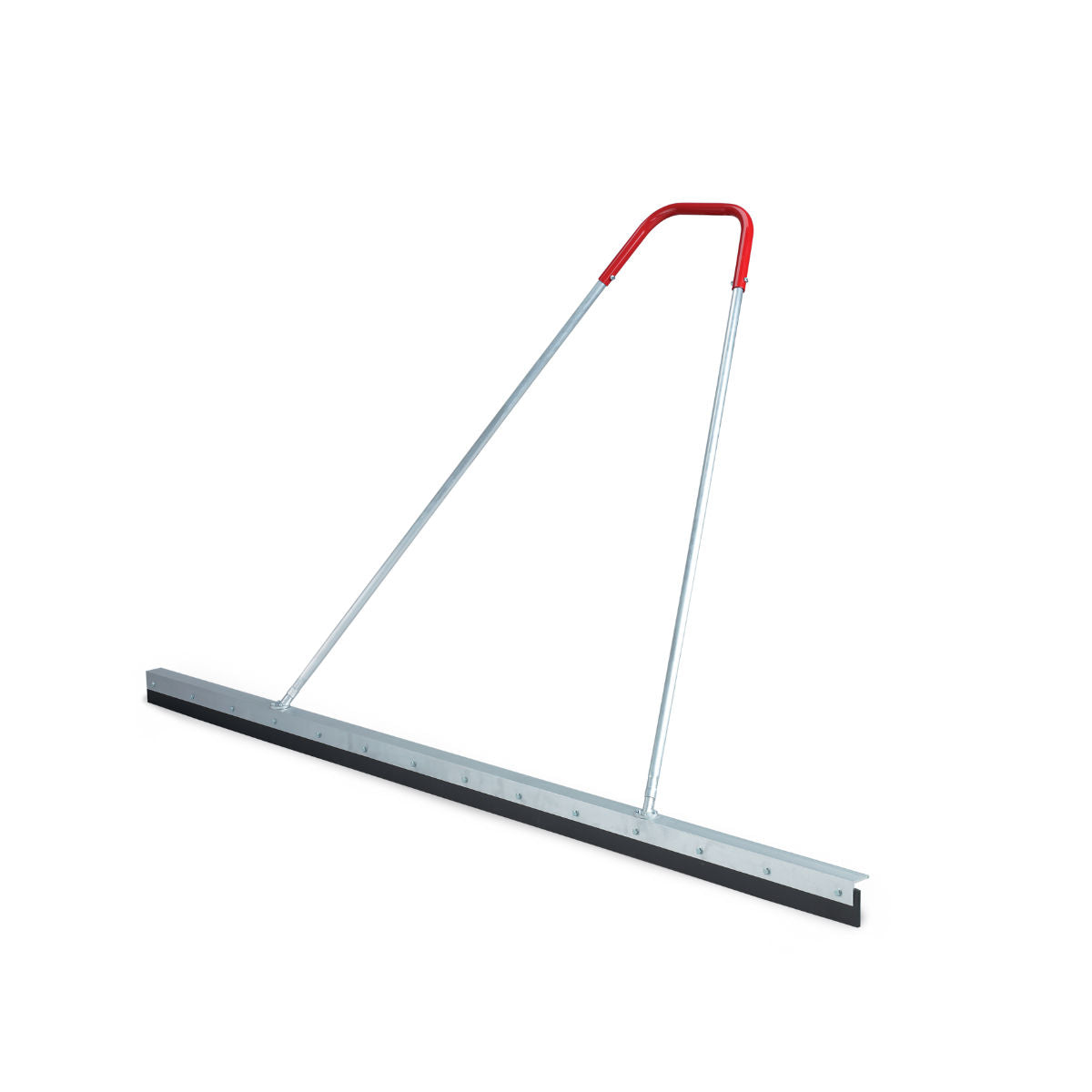

scrape

The top layer of the tennis court surface is removed manually with scrapers or motorized with brooms and a milling machine. It is important to ensure that this is done evenly, so that no excessively deep holes are scraped into the tennis courts, and that enough material is removed to prevent the tennis court surface from becoming thicker and less permeable to water each year.

Sprinkle

After scraping off the old material, fresh brick dust is spread onto the tennis court. A guideline for this is 2 to 2.5 tons per court. This can be done manually with a brick dust shovel or, for example, with a spreader such as the Sandy II.

The new brick dust should be spread evenly and leveled with a broom or drag net. If there are depressions along the baselines and in the playing field, it is recommended to fill and level these before spreading the dust.

Sandy sanding machine

1.685,00 €

brick dust pen

348,00 €

hand plane

235,00 €

brick dust shovel

33,00 €

Brick dust distributor

169,00 €

brick dust slider

70,00 €

Slurrying or rolling

After spreading the infill, the tennis court surface needs to be compacted. This is mainly done in two ways: rolling or grouting.

In the rolling method, the tennis court is moistened after the infill is applied and compacted with a motorized roller. Afterwards, the court is swept with a broom and thoroughly watered over several days until it has reached the necessary hardness.

During the grouting process, the applied brick dust is spread and smoothed like liquid concrete using plenty of water. Once the water has dried, it is also smoothed with a screed brush.

Tennis court roller USP III

8.539,55 €